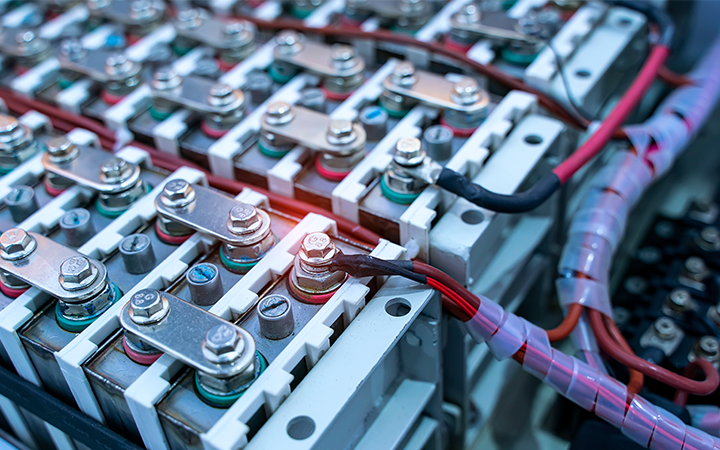

In recent years, the proliferation of batteries—especially lithium-ion batteries—in consumer electronics, electric vehicles, renewable energy storage, and other applications has revolutionized how we live and work. However, with their widespread use comes the critical responsibility of ensuring their safety. Battery safety testing is essential to prevent failures that can lead to fires, explosions, or other hazardous events. Implementing best practices in battery safety testing not only helps manufacturers meet regulatory standards but also enhances consumer trust and minimizes risks.

This blog explores the key principles, methodologies, and best practices for conducting comprehensive battery safety tests. Whether you're a battery developer, manufacturer, or quality control professional, understanding these practices is vital for producing safe and reliable energy storage solutions.

1. Understanding the Importance of Battery Safety Testing

Batteries, especially lithium-ion types, are complex electrochemical systems. While they offer high energy density and long cycle life, they also pose safety risks if not properly designed, manufactured, or handled. Safety testing helps identify potential failure modes, weak points, and abnormal behaviors under various conditions.

Why is battery safety testing critical?

- Prevent accidents: Fire, explosion, or leakage incidents can cause property damage and injuries.

- Regulatory compliance: Standards like UL 2054, IEC 62133, and UN 38.3 mandate specific safety tests.

- Consumer confidence: Demonstrating rigorous safety measures builds trust.

- Product development: Early detection of safety issues informs design improvements.

2. Fundamental Principles of Battery Safety Testing

Before diving into specific tests, it's essential to understand core principles that underpin effective safety testing:

- Worst-case scenario analysis: Tests should simulate extreme conditions to identify potential failure modes.

- Repeatability: Tests must produce consistent results to validate safety margins.

- Traceability: Proper documentation ensures reproducibility and compliance.

- Risk mitigation: Tests should aim to uncover hazards before product deployment.

- Calibration and validation: Equipment used in testing must be calibrated regularly to ensure accuracy.

3. Preparing for Safety Testing: Best Practices

1. Define Testing Objectives Clearly

Identify what safety aspects you want to evaluate—thermal stability, mechanical integrity, electrical safety, etc. Establish specific test parameters aligned with standards and intended use cases.

2. Develop a Test Plan

Create a detailed plan covering:

- Test types and procedures

- Equipment and instrumentation required

- Safety measures and emergency protocols

- Acceptance criteria and pass/fail conditions

- Documentation procedures

3. Use Representative Samples

Test samples should mirror actual production units in terms of chemistry, form factor, and manufacturing quality. Include multiple samples to account for variability.

4. Ensure Proper Safety Measures

Testing can be hazardous. Use appropriate protective gear, fire suppression systems, and conduct tests in controlled environments like fume hoods or blast chambers.

4. Key Battery Safety Tests and Best Practices

1. Overcharge and Overdischarge Tests

Purpose: Assess the battery's response to charging beyond its maximum voltage and discharging below its minimum voltage.

Best Practices:

- Use precise power supplies capable of controlling voltage and current.

- Incrementally increase voltage/capacity to identify thresholds.

- Monitor temperature, voltage, and current continuously.

- Conduct tests in a controlled environment with fire suppression systems in case of thermal runaway.

2. Thermal Abuse Tests

Purpose: Simulate conditions like overheating or external heat sources to evaluate thermal stability.

Common Tests:

- Thermal Shock: Rapid temperature cycling between high and low temperatures.

- Heat Exposure: Exposing the battery to elevated temperatures (e.g., 130°C) for specified durations.

- Hot Car Test: Placing batteries in a heated environment mimicking real-life scenarios.

Best Practices:

- Use calibrated thermal chambers.

- Record temperature profiles meticulously.

- Observe for venting, swelling, or fire.

3. Mechanical Abuse Tests

Purpose: Assess how batteries respond to physical impacts, punctures, crushes, or drops.

Tests Include:

- ** Crush Test:** Applying a compressive force to simulate crushing.

- ** Penetration Test:** Puncturing the battery with a metallic object.

- ** Drop Test:** Dropping the battery from specified heights onto various surfaces.

Best Practices:

- Use standardized fixtures and measuring devices.

- Conduct tests in contained environments.

- Ensure safety protocols are strictly followed.

4. Electrical Abuse Tests

Purpose: Simulate electrical faults that could occur during use.

Types:

- Short Circuit Test: Connecting the positive and negative terminals with low resistance.

- Reverse Polarity Test: Connecting terminals in reverse.

- Overcurrent Test: Applying excessive current during charging/discharging.

Best Practices:

- Use current-limiting devices.

- Monitor parameters continuously.

- Prepare for thermal runaway scenarios.

5. Overtemperature and Fire Tests

Purpose: Evaluate how the battery safety testing behaves under high-temperature conditions, including its propensity to ignite.

Methods:

- Exposing batteries to direct flame or high-temperature ovens.

- Conducting open-flame ignition tests on vented batteries.

Best Practices:

- Use fire-resistant containers.

- Conduct in designated safety zones.

- Document incident outcomes thoroughly.

6. Environmental Tests

Purpose: Assess performance and safety under environmental stressors like humidity, vibration, and altitude.

Methods:

- Humidity Chamber Testing: To evaluate corrosion and leakage.

- Vibration Testing: To simulate transportation and handling conditions.

- Altitude Testing: To assess performance in low-pressure environments.

Best Practices:

- Follow standards such as IEC 60068.

- Use appropriate environmental chambers.

- Record all test parameters meticulously.

5. Data Collection, Analysis, and Documentation

Accurate data collection is vital. Use calibrated instruments to record voltages, currents, temperatures, and visual observations. Establish clear criteria for pass/fail thresholds based on standards and safety margins.

Post-test analysis should include:

- Identifying failure modes

- Correlating test conditions with observed behaviors

- Recommending design or process improvements

Comprehensive documentation should cover:

- Test procedures and conditions

- Observations and measurements

- Deviations and anomalies

- Conclusions and safety assessments

6. Regulatory Standards and Certification

Compliance with international standards ensures that batteries meet safety requirements:

- UL 2054: Standard for household and commercial batteries

- IEC 62133: Safety requirements for portable sealed secondary cells

- UN 38.3: Transportation testing for lithium batteries

- UL 1642: Lithium batteries safety standards

Adhering to these standards involves conducting specific tests and documenting results accordingly. Certification validates the safety and reliability of the product.

7. Continuous Improvement and Safety Culture

Battery safety is an ongoing process. Incorporate lessons learned from testing and field performance into design and manufacturing processes. Foster a safety-first culture among design engineers, quality professionals, and manufacturing staff.

Regularly review and update testing protocols to incorporate advances in technology and emerging safety concerns.

Conclusion

Conducting thorough battery safety test is a cornerstone of responsible battery development and deployment. Best practices encompass meticulous planning, adherence to standardized procedures, rigorous testing under simulated worst-case scenarios, and comprehensive documentation. By integrating these practices, manufacturers can significantly mitigate safety risks, ensure compliance, and deliver reliable, safe energy storage solutions to consumers worldwide.

Remember, safety testing is not a one-time activity but an integral part of the entire product lifecycle. Prioritizing safety not only protects users but also enhances brand reputation and market competitiveness.

Let's Connected

Name: Dynamic Manufacturing, Inc.

Address: 4711 W Division St, Chicago, IL 60651, United States

Phone: +1 708-343-5833

Map: https://maps.app.goo.gl/KwpdEoqAHEMBtn6B6